A Contradiction of Intent: How Carbon Capture Perpetuates Fossil Fuels

By Sheri Deal-Tyne, MPP

A CO2 injection well in operation as part of an enhanced oil recovery (EOR) operation at a mature oil field. Source: US Department of Energy

Unless you are a climate denier, by now there is a pretty good consensus that to protect ourselves from catastrophic global warming, the entire earth’s inhabitants must decarbonize. Where there is less agreement is how exactly decarbonization should proceed. Carbon Capture and Storage (CCS) is increasingly promoted as essential in our decarbonization effort. This piece examines the contradiction of carbon capture: the fact that it is being posed as a climate solution when it is the opposite. Every stage of CCS increases the use of fossil fuels, the very drivers of climate change.

Since the burning of fossil fuels creates greenhouse gases, and greenhouse gases cause global warming, the logical conclusion is that we need to stop burning fossil fuels. In fact, this is the recommendation made by climate scientists, environmental activists, the United Nations Development Programme, the World Health Organization, and even engineers. Ironically but unsurprisingly, the fossil fuel industry wants to use CCS as an excuse to continue producing and burning coal, petroleum, and natural gas.

The purported benefit of CCS is that it captures, and therefore prevents, the carbon dioxide (CO2) emissions from entering the atmosphere. The general argument is that the use of carbon capture essentially “decarbonizes” the fossil fuel. This is not the case. CCS increases the use of fossil fuels.

What’s All this Fuss About Carbon Capture?

The fossil fuel industry aggressively promotes CCS, a mechanical, chemical, and industrial process with multiple stages. CCS refers to the capture of CO2 emissions at the source of the pollution, e.g., a smokestack on a coal plant. CCS does not refer to biological types of carbon sequestration such as in forests or wetlands.

In the first stage, the CO2 is captured and separated from other emissions. In the second stage, the CO2 is compressed into liquid form. In the third stage, the compressed CO2 is pumped into and transported via pipelines. In the fourth stage, the liquid CO2 is injected into the earth at the sequestration site or the oil well or used to make various products. It’s important to know that all these stages of the CCS process are energy intensive and increase the use of fossil fuels.

Stage I: Capture

Capture equipment requires its own energy source. These energy sources will almost always be generated by a fossil fuel. On power generation plants, such as a coal plant, a portion of the energy being generated at the plant is redirected for the CCS capture equipment; this is known as the parasitic load. In some cases, separate power generators have been constructed to power the CCS capture equipment. For example, the carbon capture equipment at a coal generating station in Texas, known as Petra Nova, was powered by “natural” gas (a fossil fuel). Either way, the power sources for the capture equipment produce their own greenhouse gas emissions, and a carbon capture unit will not be affixed to them. Even if it were, it would again require its own power source (which means more fossil fuels).

The bottom line of carbon capture is that it takes significantly more energy to capture the CO2 than the original facility required.

What Does CCS Have to do With Hydrogen?

The production of hydrogen is an industry that CCS proponents want to “decarbonize” by adding carbon capture. A key thing to know about hydrogen is that it does not exist freely in nature and can only be produced from other sources. Currently, 99.6 percent of that production is from fossil fuels! More specifically, 95 percent of the hydrogen produced in the United States is derived from methane in a process known as steam methane reforming (SMR). SMR uses heat and pressure to convert the methane in natural gas (a fossil fuel) to hydrogen and CO2. The CO2 emissions from hydrogen production are extensive. Each ton of hydrogen produced releases nine to twelve tons of CO2 into the atmosphere.

Concerns about these excessive CO2 emissions from hydrogen production have led to the promotion of blue hydrogen, which is manufactured by combining SMR with CCS. In other words, blue hydrogen is hydrogen derived from natural gas (a fossil fuel) while capturing the CO2 emissions from that process. Currently, one percent of the world’s hydrogen production is blue hydrogen.

Blue hydrogen is referred to as being “clean” or “low carbon.” For example, an industry report by the Hydrogen Council uses the terms clean hydrogen, renewable hydrogen, and low carbon hydrogen:

Blue hydrogen is promoted as a low carbon solution. The contradiction is that blue hydrogen is derived from a fossil fuel. When carbon capture proponents push hydrogen, they are talking about hydrogen that is derived from natural gas (a fossil fuel). Recent peer-reviewed research indicates blue hydrogen’s carbon footprint is twenty percent greater than burning either natural gas or coal directly for heat and sixty percent greater than using diesel oil for heat. Another way of saying this is that it requires more energy to produce hydrogen than the energy benefit derived from hydrogen.

What Does CCS Have to Do with Ethanol?

Plans are underway in the Midwest to capture CO2 at ethanol facilities. Ethanol has gained traction as a “renewable fuel,” but here in the United States, ethanol is a fuel additive that is blended with gasoline (petroleum) at a ten percent rate (so one part ethanol to nine parts gasoline). A bill has been introduced by senators of some Midwestern states to increase the blend percentage to fifteen. Supporters of the Midwest CCS projects claim they will be producing a “low carbon” fuel. Even at fifteen percent, this does not account for the remaining 85 percent gasoline, a fossil fuel. Investing in any plans or projects related to ethanol in the US overwhelmingly relies on—and, indeed, encourages—the continued use of the gasoline (a fossil fuel) with which it is blended.

What about CCS and Plastics?

Shell Polymers Monaca, a project of the multi-national fossil fuel corporation, is a new ethane cracker plant in Pennsylvania. Ethane, like methane, is essentially fossilized plankton that fell to the bottom of the sea millions of years ago and became trapped inside layers of shale. It’s a liquid fossil that turns into vapor when it comes out of the ground along with methane (natural gas) during fracking operations. Unlike methane, ethane is not much good as burnable fuel. Instead, its value as a fracking waste product is in the making of plastics.

The first step in this process, called ethylene cracking, uses extreme amounts of heat energy (pyrolysis) to crack off the hydrogen atoms from molecules of ethane to produce ethylene. Molecules of ethylene, which is also a gas, can then, under pressure, all be linked together to make polyethylene resin, the building block for all kinds of plastics products, from dry cleaner bags (low density polyethylene) to Barbie dolls (polyvinyl chloride).

This Shell ethane cracker plant is one of the largest. It converts the ethylene into small plastic pellets known as “nurdles,” which are precursors to other types of plastic products. Nurdles also cause their own brand of environmental harm. The pellets are minimally regulated and spills or leaks from the production plants are common. Nurdles also often spill while being loaded on and off trains where they accumulate on tracks and then wash into rivers, lakes, or coastlines when it rains. Before the Shell cracker opened, citizen scientists worked to measure the existing nurdle presence in the surrounding waters, and they will be monitoring the waters going forward to detect increases.

Two more ethane cracker plants are being planned along the Ohio River, one in Ohio and another in West Virginia. The Gulf Coast region and Texas are home to multiple ethane cracker plants. Including the newly opened Shell plant, there are thirty-five ethane cracker plants in the US alone. CO2 emissions from ethane cracker plants are problematic. A cracker plant generates one and a half metric tons of CO2 for every metric ton of ethylene produced. CCS is touted as a solution to the excessive CO2 emissions. To date, no ethane cracker plants are equipped with carbon capture technology. Shell’s website says this about plans for CCS at their new plant: “When suitable sequestration sites or CO2 utilization opportunities become available, the site will be able to feasibly add carbon capture technology to the process line-up.”

Stage II: Compression

After the CO2 has been captured, it is usually compressed into a supercritical fluid. Compression is done at the capture site. This process also requires an energy source, which is again a fossil fuel. Like the capture stage, compression is achieved by increasing the parasitic load. The compression of CO2 is an energy intensive procedure that involves multi-stage complex compressors and a power-generated cooling process. Accordingly, compressing the CO2 demands that more fossil fuels be added to the CCS equation.

Stage III: Transport

Transporting large volumes of supercritical CO2 by any means other than pipeline is unrealistic. In fact, industry maps predicting the infrastructure requirements of large-scale CCS have estimated a need for 65,000 miles of new CO2 pipelines that will crisscross multiple states.

The transport pressure and temperature conditions must remain constant from beginning to end of the pipeline. If pressure inside the pipeline is reduced, the supercritical fluid CO2 will change into gaseous phase, resulting in mechanical challenges to the pipeline.

Hence, the flow of the CO2 is driven by compressors and subsequently requires the use of additional booster compression stations along the route of the pipeline. The necessary monitoring points, compressor stations and block valves all require a power source, and this power source is, once again, a fossil fuel.

Stage IV: Use and Storage

EOR

Enhanced oil recovery (EOR) is just another way of extracting more oil. EOR entails injecting CO2 into nearly depleted oil wells, flushing more oil from them and, hence, extending their lifespans. The CO2 acts to lower the oil’s viscosity, enabling it to rise to the surface more easily. EOR has been conducted in the US since the 1970s. Initially, the CO2 used for EOR came from naturally existing reservoirs. Carbon capture technology was invented by the fossil fuel industry to use in EOR.

Of all the captured CO2 from current carbon capture projects in the United States, 94 percent is used for EOR. It is perverse to use CCS to theoretically decarbonize a fossil fuel energy source only to turn around and use the captured CO2 to produce more fossil fuels, which will in turn generate additional CO2 emissions. This is arguably the most abhorrent contradiction of CCS, which demonstrates clearly that CCS is a fossil fuel expansion program that extends the life of an industry that should instead be terminated.

Storage

The purported storage areas for the captured, compressed, and piped CO2 are deep underground. Only certain locations in the US are underlain with reservoir rock thought suitable for storing CO2. For example, the state of Iowa has only a small area with the geologic make-up necessary for CO2 storage, and thus any CO2 captured in Iowa must be transported by pipelines to other states.

Sequestering CO2 is also an energy intensive process. The storage areas can be thousands of feet deep, and the pressurized CO2 is injected into the Earth using pumps powered by fossil fuels.

One Word: Plastics

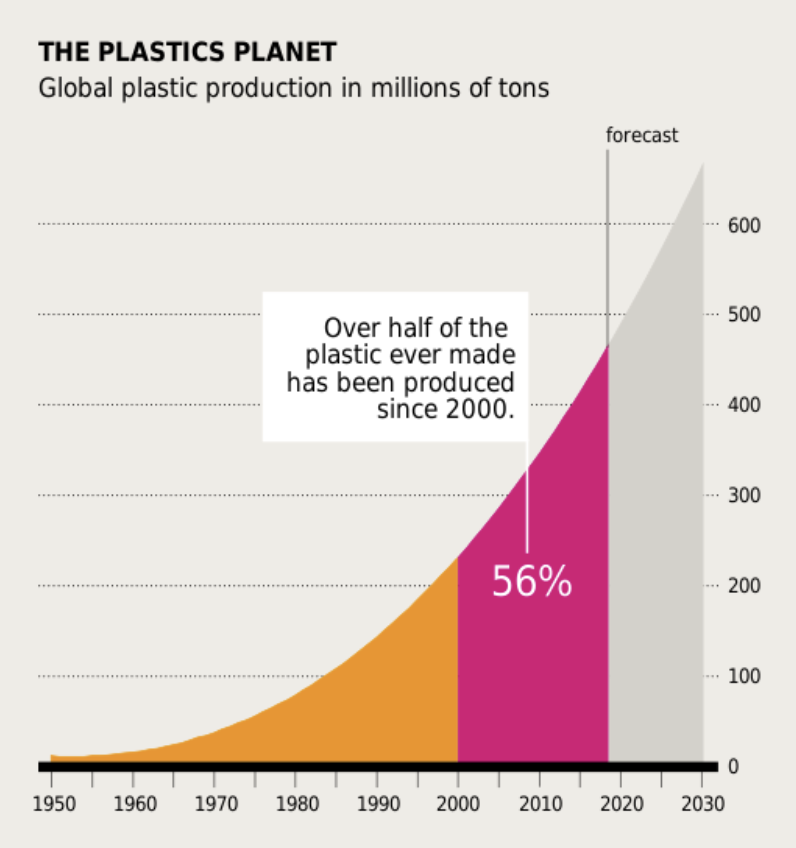

Scientists estimate that our oceans currently hold 75 to 199 million metric tons of plastic. A recent study calculates that blue whales ingest between 5.5 to 96 pounds of microplastics every day. Microplastics have also been detected in human placenta, breast milk, and human blood. Globally, plastic waste is projected to triple by 2060; less than a fifth of that total will be recycled.

Plastics are made from fossil fuels. Now researchers are studying the potential for using captured CO2 to make plastics. You may hear the acronyms CCU or CCUS within discussions about carbon capture. The “U” in CCU or CCUS stands for “Utilization.” The “U” is referring to the use of the captured carbon in some way, such as in EOR, or for creating plastics. But plastics made from captured CO2 are not free of gas and oil as fossil fuels are still needed as inputs in the manufacturing process.

Converting captured CO2 into plastics does nothing to solve the plastic crisis. In addition to the need for fossil fuels as inputs, the captured CO2 will nevertheless come from a capture unit that is powered by fossil fuels and the plastics will continue to be non-biodegradable.

Graph 1. Global Plastic Production. Source: PLASTIKATLAS

Driving the Contradiction: Carrots and No Sticks

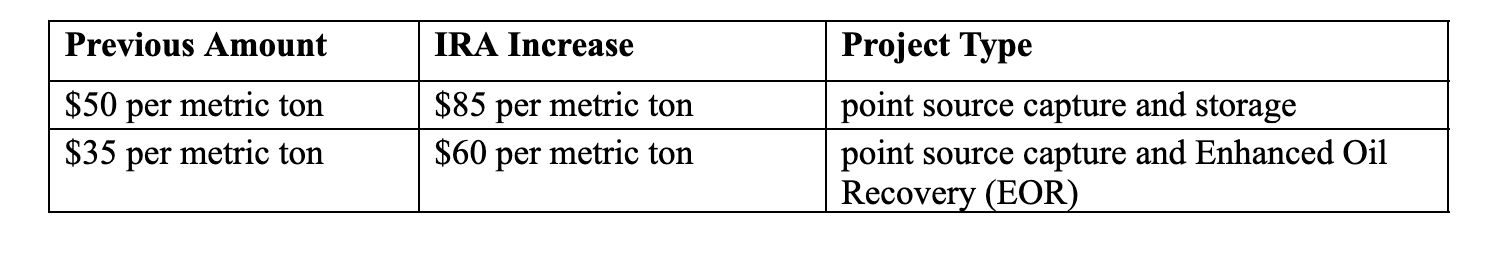

The 45Q Tax Credit became part of the IRS Tax Code in 2008 and has been increased over time. The purpose of the 45Q is to financially motivate industries to conduct carbon capture at their facilities. It is, in essence, a “pay-the-polluter” scheme. The passage of the Inflation Reduction Act (IRA) in August of 2022 included increases to the 45Q credits.

Chart 1. 45Q Tax Credit Amounts

The IRA did not phase out the credit for EOR, but instead raised the credit, providing more financial inducement to conduct EOR. The absurdity of a policy supposedly intended to decarbonize an industry while simultaneously incentivizing the production of more fossil fuels cannot be overlooked.

The caveat of a tax credit is that the industry receiving the credit must be paying taxes, thus making a profit. Another change to the 45Q in the IRA makes it possible for industries not making a profit to receive the 45Q credit as a direct payment. Other changes include lowering the total amount of CO2 that a project is required to capture each year to qualify for the 45Q credits. Additionally, there was significant funding passed for carbon capture projects in the Infrastructure Investment and Jobs Act (IIJA) that include incentives like grants and low-interest loans for building CO2 pipelines and hydrogen hubs.

All these changes raise grave concerns that industries will be in the business of collecting the 45Q, rather than creating and supporting a legitimate business that provides a necessary service. If a coal plant or a natural gas facility can remain profitable by polluting because of the 45Q, there is no incentive for them to cease producing fossil fuels and the greenhouse gases associated with them. When all is said and done, the 45Q incentivizes industries to produce CO2 emissions, rather than eliminating them.

As a case in point, the largest coal plant in New Mexico was scheduled to be retired in 2022. At the last minute, an obscure corporation, which identifies itself as a CCS developer, announced plans to keep the coal plant operational by installing the largest carbon capture system on a power plant. In an email to a journalist, the CEO admitted that the project can be “economically successful” due to the 45Q tax credits.

Conclusion

Each stage of the CCS process increases the use of fossil fuels, which in turn produce their own greenhouse gas emissions. Contradicting the science-based mandate to phase out and ultimately end fossil fuel production, CCS extends the lifetime of fossil fuel facilities. Taxpayer funded 45Q tax credits incentivize the production of CO2 emissions, by financially rewarding industries to generate CO2 emissions so they can capture and pipe them and store them in the Earth. Taxpayer funded 45Q also incentivizes increased petroleum production through EOR, which in turn generates even more CO2 emissions. Appallingly, CCS pays the polluters to pollute.

Regardless of the narrative pushed by the fossil fuel industry, CCS is the utter antithesis of decarbonization. We absolutely should not be funding CCS and enabling the fossil fuel industry with taxpayer monies.

Appendix: The Other Greenhouse Gas

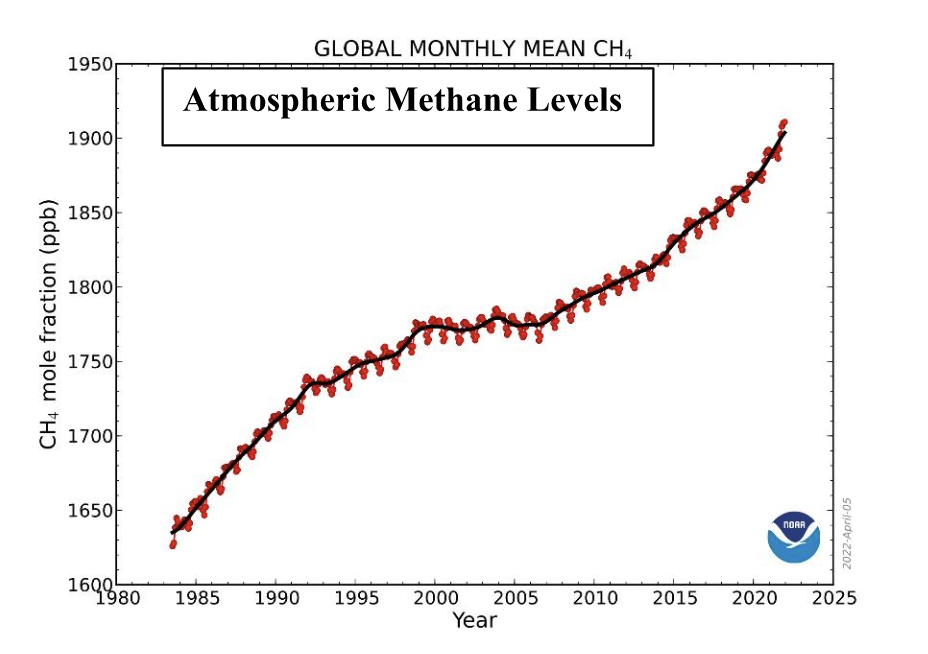

The term “natural gas” is misleading and sounds as though it might fall under the category of renewables, but natural gas is methane. The burning of methane for fuel releases less CO2 into the atmosphere than burning coal or petroleum, which contributes to the perception that natural gas is an environmentally friendly alternative. However, methane is an extremely powerful greenhouse gas and its use as an energy source comes with its own set of environmental and health harms.

Methane is used as a feedstock for blue hydrogen and for ethylene plastics. Most of the natural gas in the US is derived via fracking. The dangers of fracking are extensive. Additionally, methane leaks or is released directly into the atmosphere at every stage of the production process. While CO2 is the major GHG, methane is eighty times more proficient than CO2 at trapping heat in our atmosphere. CCS only captures CO2 emissions and does not capture methane emissions.

Graph 2. Global Atmospheric Methane Levels Over Time. Source: National Oceanic and Atmospheric Administration